NEWS

——

Genfo Transformation (1): Breaking the Situation and Seeking to Change

2023-11-24

Since its establishment in 2000, Genfo has attached great importance to research and development management, and regards product development as the foundation of the company.

After years of accumulation, Genfo has developed multiple widely recognized flagship products and mastered a series of industry-leading product technologies. However, in the face of an uncertain business environment and gradually evolving user needs, Genfo's R&D management has also exposed many shortcomings and urgent challenges that need to be addressed.

With unwavering confidence and determination in change, Genfo has made great efforts to improve its research and development capabilities, product quality, and management system of the research and development center. So, what have been the results of the change in Genfo's research and development center since the beginning of the six months of change? What measures and actions have been taken?

1. R&D Organizational Change

The organizational transformation of Genfo R&D mainly focuses on three aspects: optimizing organizational structure, upgrading organizational model, and building a talent team at four levels

1 ► Organizational structure optimization

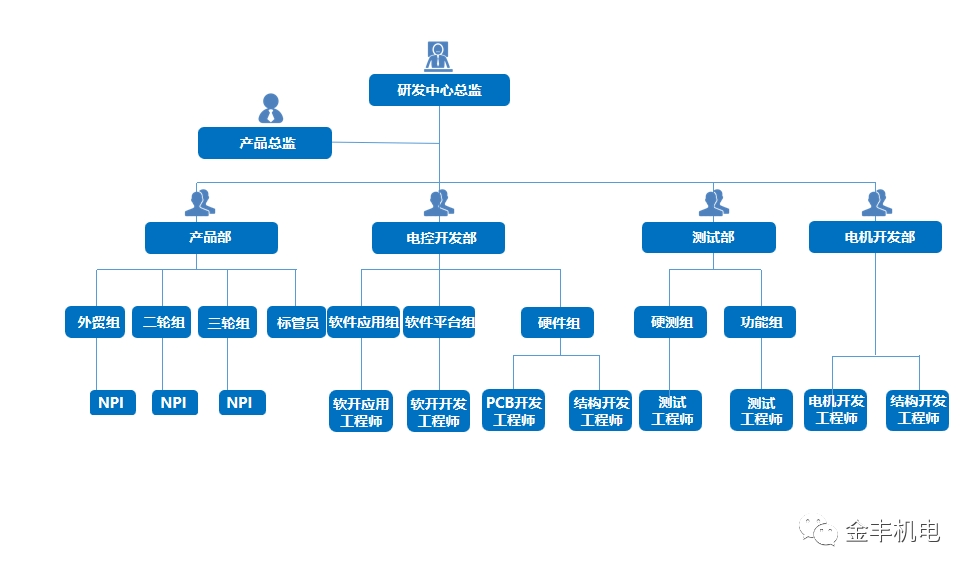

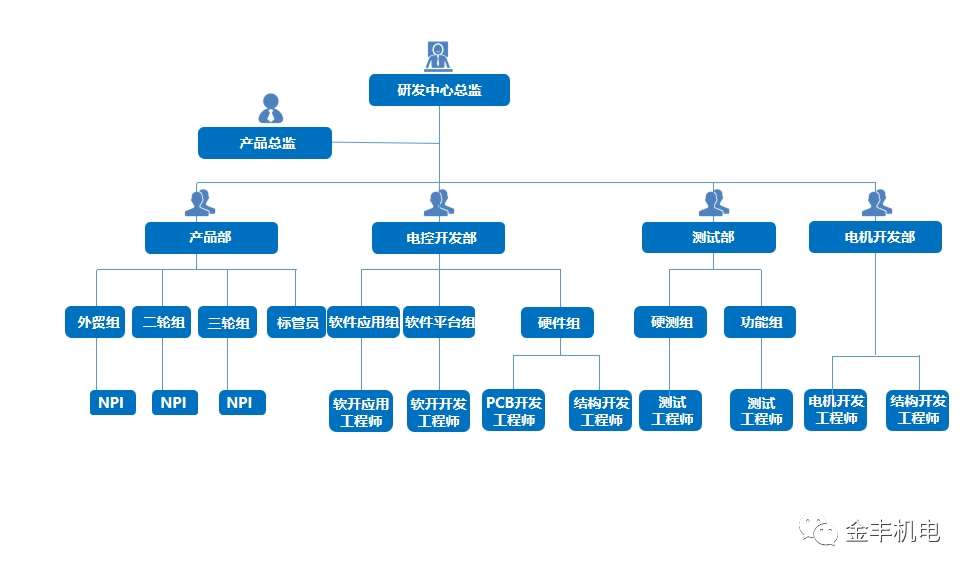

Based on the company's business characteristics, the R&D center has optimized the organizational structure as follows:

The product department is responsible for confirming the requirements of new products, project introduction, process tracking, and sample delivery.

The Electric Control Development Department is responsible for the software, hardware, and structural development of the motor controller, which is divided into a platform group (responsible for the development of the underlying algorithm platform and the construction of the R&D basic platform) and an application group (responsible for the development and application of functional modules, and supporting the resolution of technical application problems).

The Motor Development Department is responsible for the magnetic circuit design, structural design, research and development process, etc. of the motor.

The testing department is responsible for conducting sufficient testing and verification of products (white box testing, black box testing), divided into hardware testing group and functional testing group (including software testing and road testing).

By optimizing the organizational structure mentioned above, the division of labor mechanism of the R&D team has been clarified, and collaborative efficiency has been improved.

2 ►Organizational Mode Upgrade

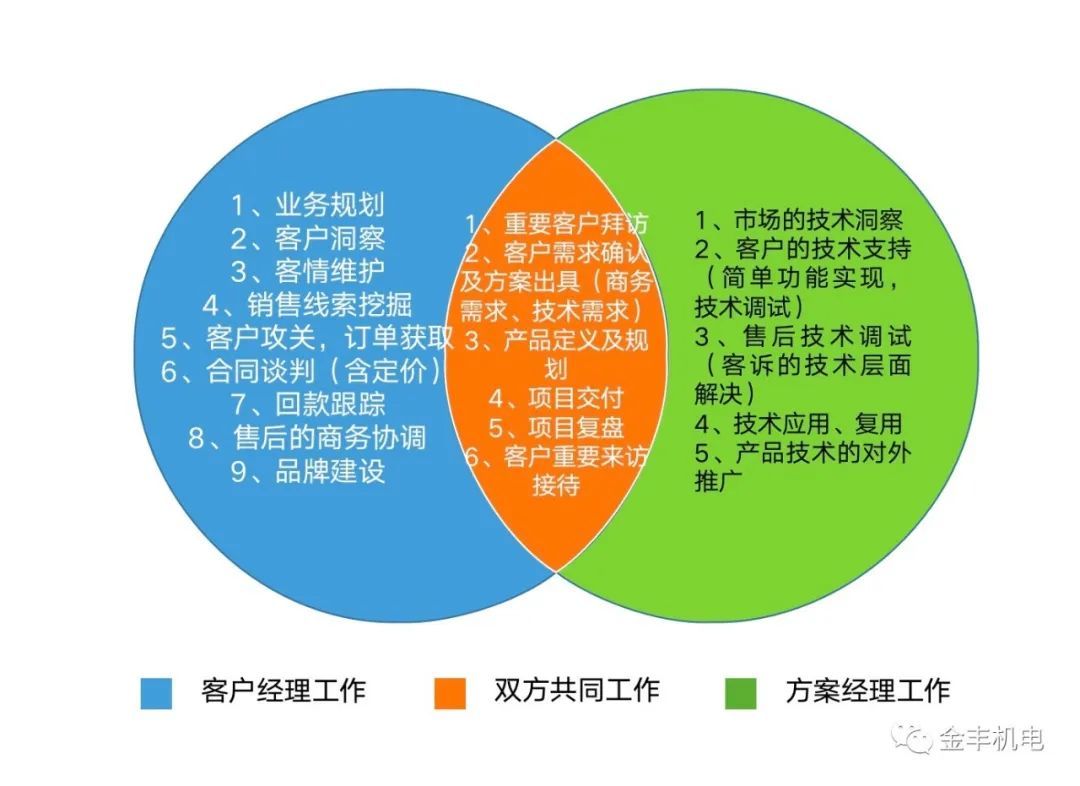

The company draws on the operational model of the "Iron Triangle" and strengthens the role of "Solution Manager" (SR) in the research and development center, mainly served by engineers from the software application group of the electronic control development department, in deep cooperation with the "Customer Manager" (AR) in the marketing center. The solution manager needs to go deep into the customer site with the customer manager, communicate with the customer firsthand, effectively translate customer needs into internal technical language, output professional product solutions, and track internal development progress to improve the operational efficiency of internal projects.

3 ►Talent echelon construction

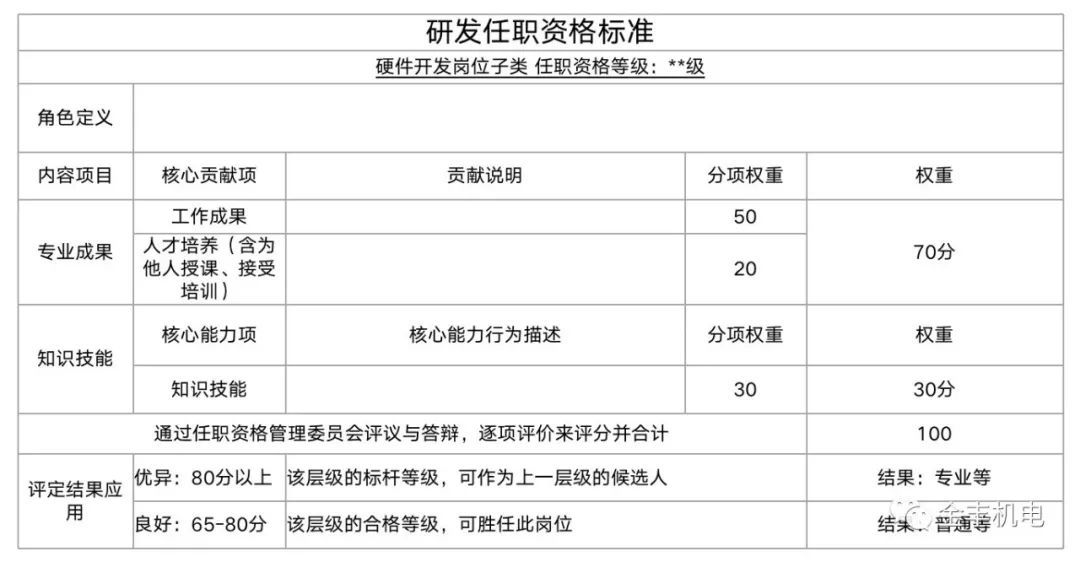

The R&D center takes the lead in implementing qualification construction, drafting and evaluating qualification standards, and conducting qualification defense. At present, all R&D students have completed their qualification defense and clarified their qualification levels.

At Genfo, job qualification evaluation is result oriented. Contribution: Ability=7:3.

The highlight of the Genfo job qualification system is that it not only has reasonable job standards, but also points out a clear, clear, and feasible "promotion path", that is, from low standards to higher standards, there is a track to follow for what needs to be learned, who needs to learn from, and where to learn.

The company provides sufficient resources and guidance for the improvement of employees' job qualifications. After the completion of the qualification defense, the results should be applied (salary adjustment, promotion) as soon as possible, so that they are not mere formality and can receive full attention and participation from employees.

In addition, the R&D center has recruited and selected dozens of excellent R&D engineers through various channels, with a total R&D team of over 60 people. After the team was formed, guided by work performance and work attitude, several team leaders were boldly promoted, such as product group leader, testing group leader, hardware group leader, software platform group leader, and software application group leader, to make up for the company's talent shortage in the "backbone" and consolidate the talent team.

What has been the process of the R&D center in this transformation

What kind of optimization? How to control process activities?

What results have been achieved?

2. R&D process change

The R&D process transformation mainly focuses on three aspects: process sorting and optimization, improvement of work methods, and improvement of R&D quality

1 ►Process sorting and optimization

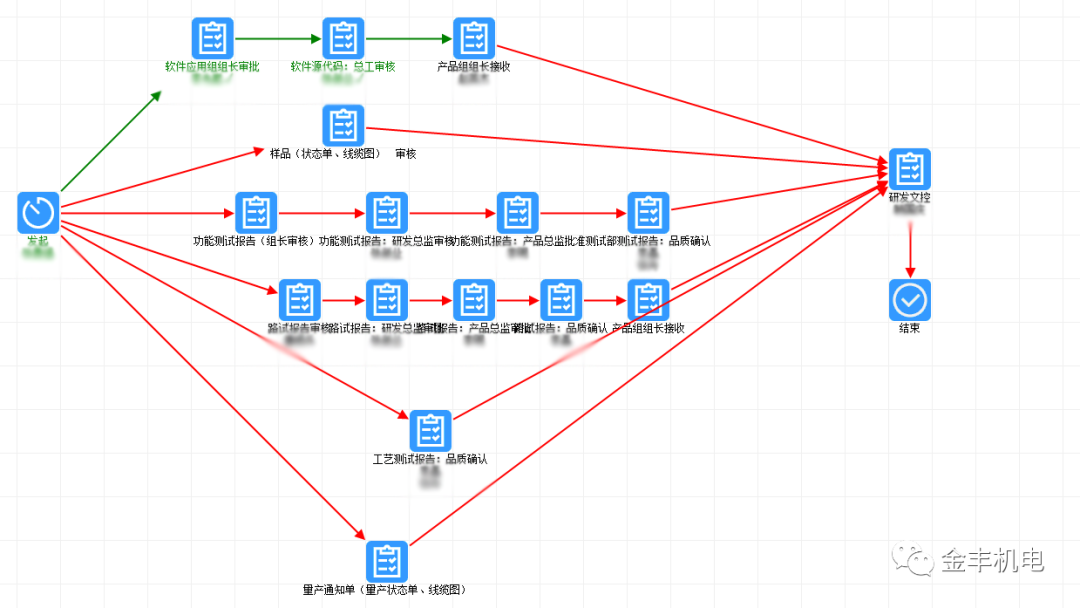

The R&D center systematically organizes and optimizes the R&D management process, dividing R&D projects into four categories based on project difficulty, degree of change, etc., corresponding to different R&D processes. Repeated discussions and optimizations were conducted on key process nodes, such as customer requirement confirmation and transmission, project initiation review, scheme design of the R&D development process, and R&D testing and verification.

2 ►Improvement of working methods

The R&D center has established and improved various work standards and specifications, such as software and hardware design specifications, and product testing specifications. Repeatedly promote and demand standards and norms to truly make them effective.

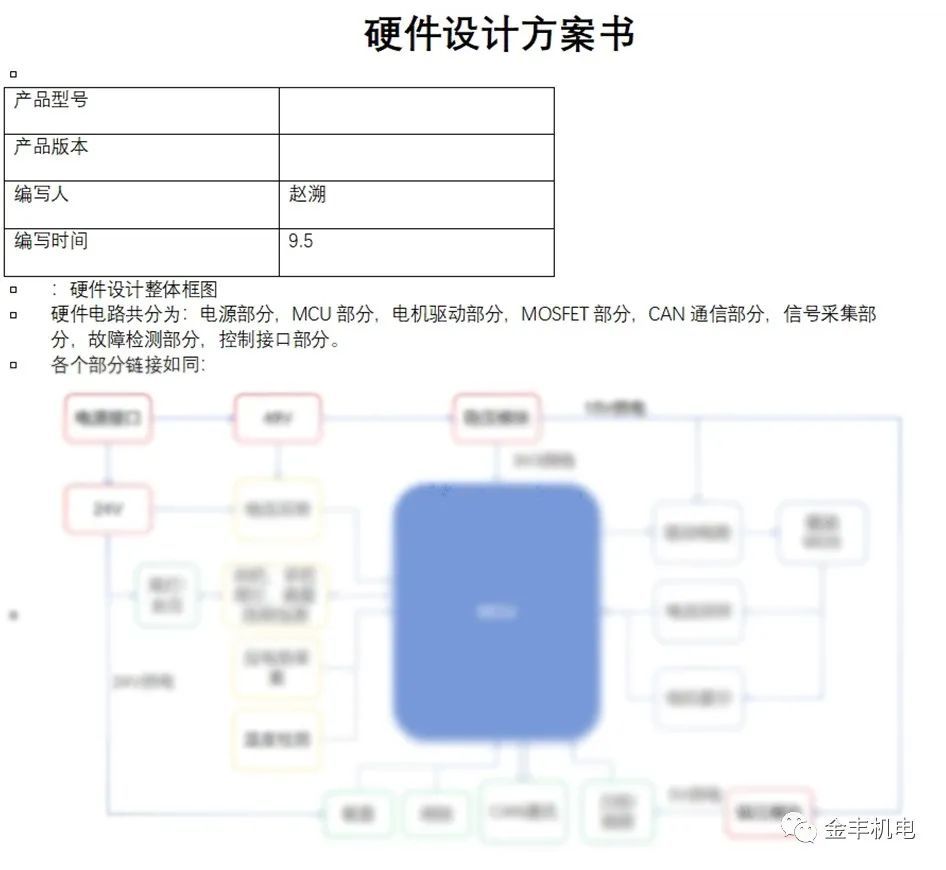

Taking the "Product Hardware Design Proposal" as an example, the proposal provides full information on the power module, MCU, motor drive, communication, and peripheral components, showcasing the working principles, parameter information, and design solutions of each module. After the output is completed by various responsible engineers, the R&D director, product department, development representatives, product directors, and customer representatives from various departments jointly participate in the review.

Part of the Product Hardware Design Proposal

In terms of hardware testing standards, in the past, hardware self-test standards were scattered and missing, often resulting in errors and repetitive work caused by non-standard self-test standards. The development of hardware self-test standards made hardware test cases clearer and standardized, and also ensured timely updates of hardware test items; Previously, the testing standards for internal hard testing engineers were single, but after improvement, more testing projects were added, including performance testing and board level testing.

The establishment of standards and norms greatly improves the work efficiency of R&D engineers, avoids unnecessary repetitive labor, and enhances the reliability of product design.

3 ►Improvement of R&D quality

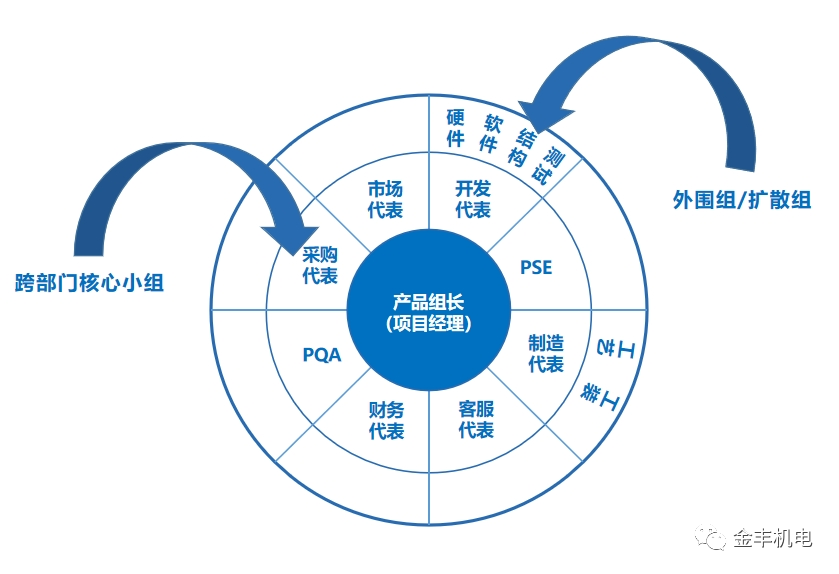

The research and development center draws on quality management tools such as APQP and FMEA to effectively strengthen the quality of research and development.

The company has repeatedly invited Six Sigma Black Belt masters to teach FMEA to research and development, marketing, manufacturing, process, quality and other teams, combining theory with practice, integrating knowledge and action, and applying what is learned.

The company's R&D project operation fully leverages the collaborative role of multiple departments to ensure quality control from the early stage. The project manager will import all project information into the information management system and add a review list during the project process to ensure the effectiveness of product reviews. All project activities are open and transparent, and the company's management and project team members can keep track of the activity situation in real time. Strengthen the supervision of the entire process management, and if there are deviations in the process activities, other members can propose them and correct them in a timely manner to avoid resource waste.

Product quality is definitely the result of the joint efforts of various departments. The review mechanism for new products has also been optimized. We invite experts from various departments to review and supervise together, fully demonstrate, and do not miss any opportunity to discover defects and improve quality. We strive to ensure that every process meets the requirements of high-quality standards.

The R&D center is on the path of breaking cocoons into butterflies and rebirth from Nirvana. To sacrifice with great ambition, dare to teach the sun and moon to change into a new sky. Although there have been some new developments in the R&D center, we are well aware that change is not an overnight matter, let alone an easy task. During the process, there are many difficulties to overcome and many habits to overcome, which require shedding a few layers of skin.

The transformation of Genfo has just begun, and there is a long way to go. But the Genfo people are not afraid of difficulties, they firmly hold onto the green mountains, and believe that refining into steel will surely transform!

086-514-87659292

086-514-87659292

sales@neway-power.com

sales@neway-power.com